Other Products

Additional to our main product lines we can also offer a wide range of ancillary products.

These are all sourced from high quality manufactures to ensure that the live up to our quality ethos.

We also experience these products ourselves through their use with our own fitting crews.

Our product range includes ...

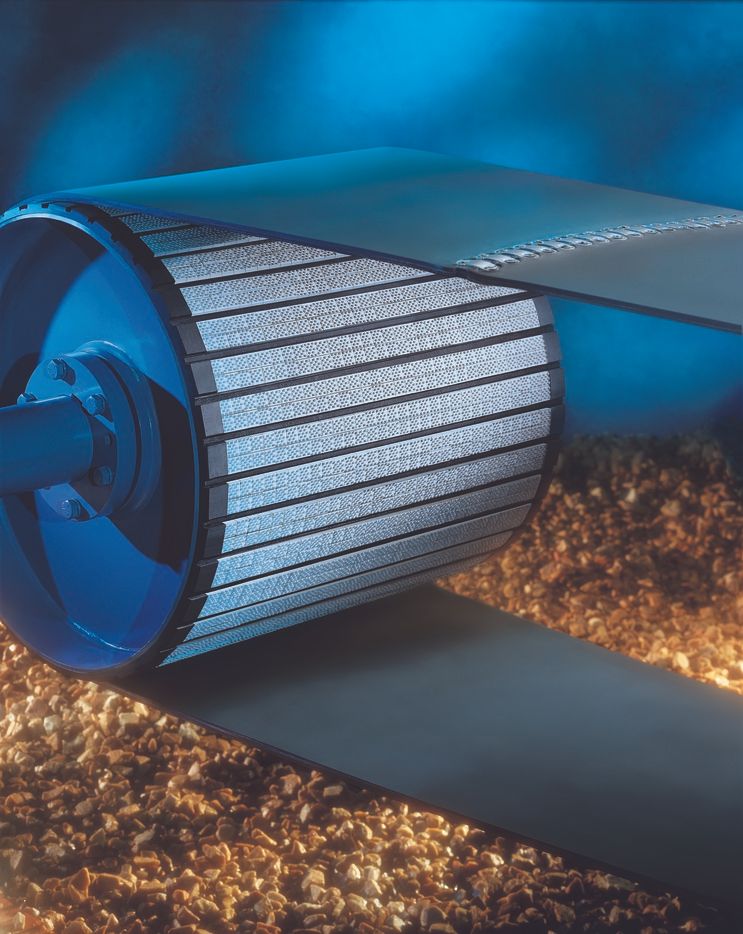

Drum Lagging

Drum Lagging is applied to a conveyor drum to improve grip, water shedding, self-cleaning and abrasion resistance. We stock a wide range of drum lagging which can be installed in our workshop by our onsite crews or even by your own fitters. Drum lagging comes in a range of materials including rubber (40 & 60 shore), ceramic and polyurethane. Drum lagging is also applied in a number using several methods including hot bonding, cold bonding, and welding. We offer premium lagging solutions from Dunlop, Flexco and Richwood all of which are available from our stock for rapid installation

Belt Tracking Units

Belt miss-tracking is a common issue often found where the conveyor has been damaged or the loading in uneven. Ideally the source of the miss-tracking should be found and eliminated, but in cases where this is difficult a belt tacking unit provides a solution. Belt tracking units are broken down into passive and active units. Passive units are fixed on the conveyor and are designed to hold the belt in one place. Typically, these are good if the belt runs consistently to one side, for instance if the conveyor has been bent out of alignment. Active tracking sets are more advanced units which sense and current the miss-tracking of the belt. Active tracking units are better where the belt wanders from side to side, and the issue is less consistent; they can adapt to movement in the belt from causes such as uneven loading or crosswinds which will be highly variable in nature

Loading Point

The Loading point is a critical area of the conveyor where good design can dramatically improve the service lifetime of the belt and reduce the ongoing maintenance costs. Impact, abrasion, spillage, and dust are all at the maximum during the loading of the conveyor and accounting for each of these issues helps to ensure that the conveyor system is reliable and efficient. For the loading point we offer the Flexco range of Impact beds comprising everything from a simple slide bed to improve sealing of fines right through to the very heaviest duty DRX range, capable of the largest lump sizes. These beds are designed to improve the sealing at the loading point whilst absorbing and dissipating the impact energy from the material, leading to a longer belt life and a cleaner, safer environment around the loading point.

Flexco Skirt Clamps

Skirt clamps work ideally with impact beds or conveyor roller support. They firmly and securely fix the skirting rubber to the loading hopper, whilst still allowing easy adjustment of the skirting rubber. The quick release system replaces the seized and corroded bolts often found on skirting systems, turning skirting adjustment from a chore into a simple short task. Flexco skirt clamps also use standard skirting rubber without the need for any specialised mouldings or consumables.

Contact us today for more information about our product range Contact Us